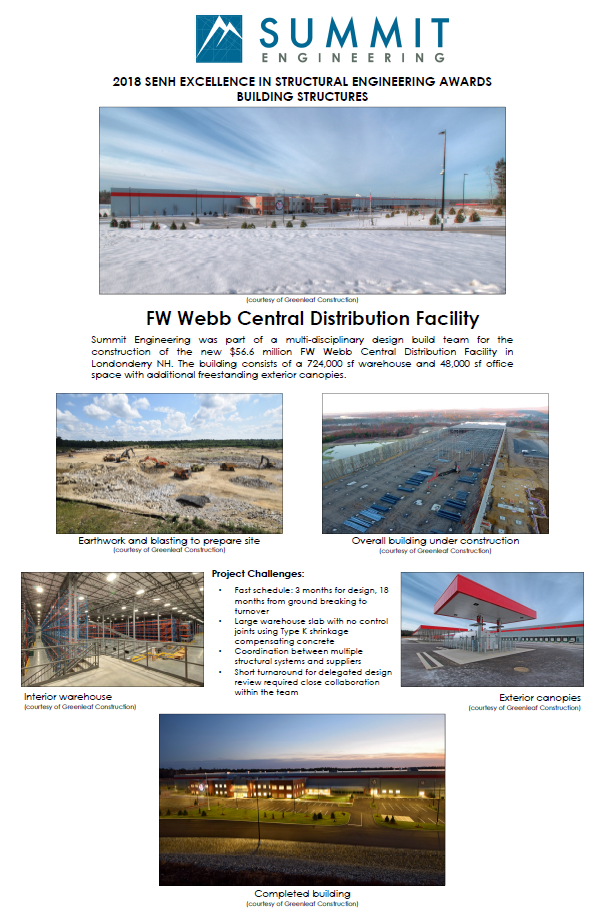

Summit Engineering was part of a multi-disciplinary design build team for the construction of the new FW Webb Central Distribution Facility in Londonderry, NH. The team consisted of Greenleaf Construction as the design builder, ci design inc as the Architect, Summit Engineering as the structural engineer of record, Avid Engineering as the MEP engineer, Hayner/Swanson as the civil engineer, Geotechnical Services Inc as the geotechnical engineer, Canam as the steel supplier, and Fabcon as the precast wall panel supplier. The team had to work closely together to design a complete building to meet the client’s needs, budget, and schedule.

The building contains 724,000 square feet of warehouse and 48,000 square feet of adjacent office space. Interior finished spacing inside the warehouse provide office space for shipping and receiving, a fitness center and locker rooms, truck detailing, forklift and Zamboni maintenance, and storage mezzanine. Additional exterior structures included canopies for the fuel island and truck cab parking, and a snow scraper. A tall stair was provided with access to the roof of the 40 foot warehouse building.

The structure of the building consists of a steel joist and joist girder roof system supported on steel columns at the interior and precast concrete panels at the exterior. The lateral system is comprised steel braced frames and precast concrete shear walls. As the building is approximately 1800 feet long and 400 feet wide it was seismically isolated into several distinct structures of approximately 400 feet each. This limited the diaphragm spans and allowed independent movement of the structure.

The construction schedule from ground breaking to final turnover took 18 months and encompassed site preparation, structural erection, and final finishes. An additional 3 months was spent on design, a very short span of time for a project on this magnitude. The tight schedule required close coordination between the design team and the builder to ensure all aspects of design were considered ahead of issuing drawings. Continued involvement during the construction process was necessary to ensure on-schedule delivery of the completed building.

As the structure had a very tight construction schedule shop drawing review and coordination involved the entire team. Reviewing the submittals for the precast panels particularly required coordination between the structural engineering, the steel supplier, the architect, and the construction team. Reviewing took place as a team, and the coordination occurred before the panels arrived on site to ensure proper placement and connection of steel to precast, and connection of precast panel to cast in place foundation.

The large warehouse space required a large flat slab and limited joints. A type K expansive concrete mix was selected to eliminate interior contraction joints and limit the number of construction joints. The slab was placed in panels of 20,000 to 40,000 square feet, with 400 to 750 cubic yards of concrete for each placement without control joints. Each placement had to meet stringent flatness and levelness criteria to achieve the overall requirements of forklift traffic and tall shelving.

Earthwork and blasting to prepare site (courtesy of Greenleaf Construction)

Overall building under construction (courtesy of Greenleaf Construction)

View of Interior of warehouse during construction

Fuel Island (courtesy of Greenleaf Construction)

Exterior (courtesy of Greenleaf Construction)

Interior (courtesy of Greenleaf Construction)

Overall completed building (courtesy of Greenleaf Construction)